|

item

|

value

|

|

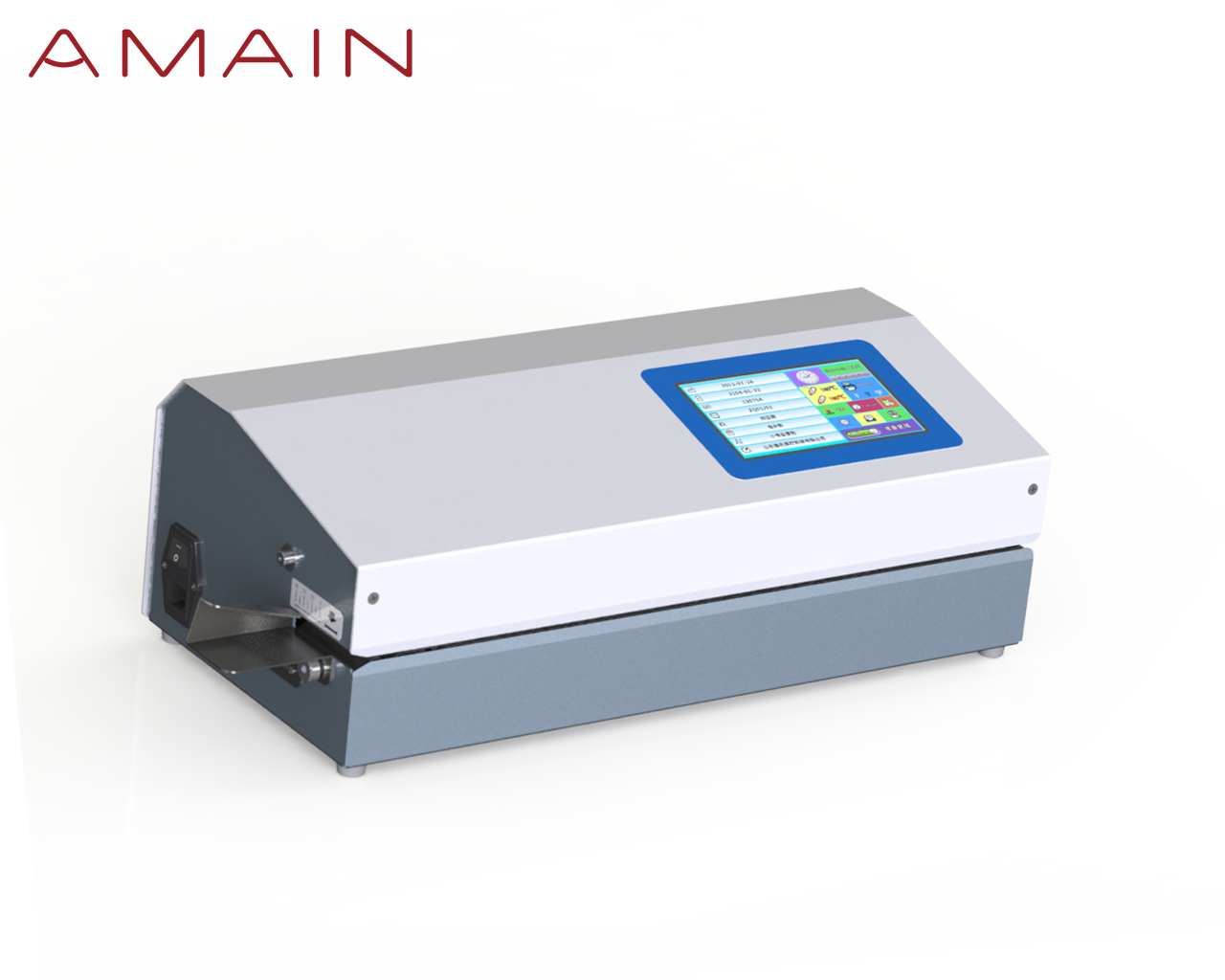

Type

|

Touch screen printing and sealing machine

|

|

Applicable Industries

|

medical sealing and packing

|

|

Function

|

Automatically adjust the print edge banding according to the parameter settings

|

|

Sealing width (model is optional)

|

12mm

|

|

Condition

|

New

|

|

Application

|

Medical

|

|

Automatic Grade

|

automatic

|

|

Driven Type

|

Electric

|

|

Power supply

|

110V/220V 50Hz/60HZ

|

|

sealing speed

|

10m/min

|

|

seal left side

|

0 ~ 35mm adjustable

|

|

Working Temperature

|

60~220℃ adjustable

|

|

Temperature error

|

Less than (+1%~-1%)

|

|

Maximum power

|

500w

|

|

Maximum Current

|

3.2A

|

|

fuse

|

5A x 2

|

|

Place of Origin

|

China

|

|

Brand Name

|

Amain

|

|

Dimension(L*W*H)

|

560 x 260 x 220mm

|

|

Weight

|

15KG

|

|

Warranty

|

1 Year

|

|

AC Power

|

According to customer requirement

|

|

Key Selling Points

|

Automatical Operate

|

|

Marketing Type

|

Hot Product 2020

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

1 Year

|

|

Product name

|

Auto-control continue sealing machine

|

|

After-sales Service Provided

|

Online Support

|

|

Keyword

|

Touch screen printing and sealing machine

|

|

Suitable for

|

meet the paper and plastic bags, paper-dimensional bags, paper bag sealing needs

|

|

Usage

|

medical supplies

|

1.7 inch color LCD touch screen, graphical user interface in English and display the print swtich, keyboard input control, built-in clock and parameters can be set with automatic storage function

2.own positive sequence (descending) sealing the counter, the number of sealing can be achieved within 0 to 9999 statistics,with print margins, print interval symbols and other special features. 3.have a rapid heating and auxiliary cooling design: equipped with a microcomputer-controlled heating and cooling mechanism to reduce sealing temperature quickly from low to high or from high in the end of the waiting time, energy efficient, fast-paced meet the operational needs of the temperature conversion, 4.computer intelligently temperature control design, operating temperature 60 ~220 ℃ arbitrarily set, temperature accuracy of less than+ 1%~-1%, four common preset temperature were 60℃, 120 ℃. 180℃.220 ℃, according to the daily users demand for fast switching user quickly select sealing temperature; 5.Operating temperature sealing temperature exceeds the set value range + 4 ℃~-4℃, the machine will automatically stop working, effectively ensure the safe operation of the seal of quality and equipment; 6.using floating constant pressure lamination structure design to meet the three -dimensional bags and bag sealing needs of different thicknesses; 7.automatic fault alarm indicator, automatic detection of the working process. a variety of failures can be automatically or prompt alarm; 8.standby time and standby temperature is adjustable,intelligent standby recovery, high-speed return to operating temperature, reducing the waiting time;

The printing system features:

2.Chinese, English, numbers and special characters in line with the print function “YY0466 -2003 medical devices used with medical device labels, signs and symbols to provide information”, the Ministry of Health to meet the requirements of the sterilization date, expiration date, batch sterilization sterilizer number, an operator code and other printing functions;

3.sterilization date, expiration date can be automatically adjusted according to the settings. intercalary month, the size of the month is automatic ally adjusted;

4.sealer comes in English and printing systems, the print clear, simple and quick to set the print matters, print font width is

adjustable, easy to put more content printed on the relatively narrow bag, printing feature a key to close also may need to close an entry, flexible, convenient, fast;

5.The system will print width values are given according to the selected print content, automated accounting print minimum bandwidth,helping the operator to determine how much of the project before printing to select the appropriate paper and plastic bags, paper and plastic bags is insufficient to achieve before sealing width reminder;