Product Description

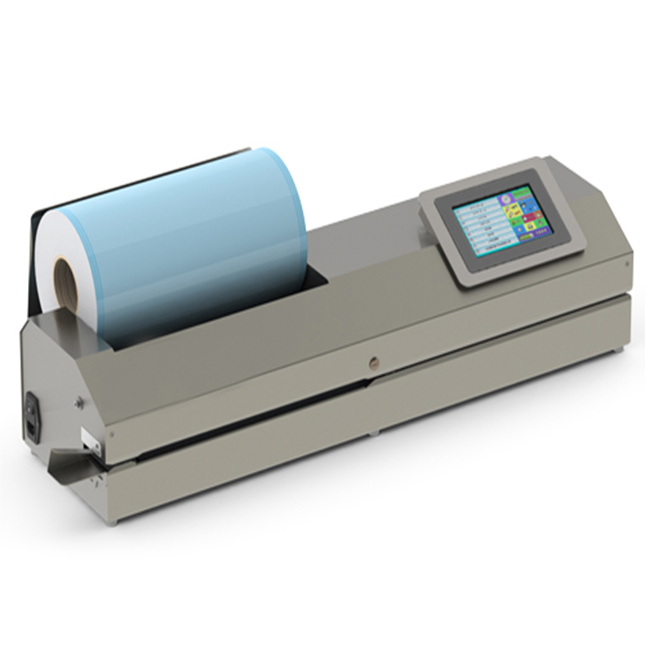

Amain OEM/ODM AMEF101-T Aluminum foil materials continuous heat sealer sealing for paper-plastic pouches 3D paper-plastic

Specification

|

item

|

value

|

|

Type

|

AMEF 101-T

|

|

Applicable Industries

|

Medical manufacturer, Medical supply factory etc.

|

|

Sealing width

|

12 mm

|

|

Sealing margin

|

0~35 mm (adjustable)

|

|

Condition

|

New

|

|

Application

|

Medical

|

|

Automatic Grade

|

automatic

|

|

Driven Type

|

Electric

|

|

AC Power

|

110V±10% 60Hz

|

|

Maximum current

|

3.2 A

|

|

Fuse

|

5A×2

|

|

Working Temperature

|

60~220℃ adjustable

|

|

Temperature error

|

Less than (+1%~-1%)

|

|

Maximum power

|

500w

|

|

Place of Origin

|

China

|

|

Brand Name

|

Amain

|

|

Dimension(L*W*H)

|

560×2 60×220(L×W×H)mm (excluding the guide plate)

|

|

Weight

|

18KG

|

|

Warranty

|

1 Year

|

|

Key Selling Points

|

High efficiency

|

|

Marketing Type

|

Hot Product 2020

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

1 Year

|

|

Storage condition

|

Temperature : 0~55℃

Humidity: ≤90%(R.H)

Atmospheric pressure: 50KPa~106KPa

|

|

Print model

|

stylus printer

|

|

Ambient temperature

|

20-40℃

|

|

After-sales Service Provided

|

Online Support

|

|

Function

|

Induction medical bag Sealing

|

|

Keyword

|

medical sealing machine

|

|

Suitable for

|

Sealed edge packing of medical supplies before disinfection

|

|

Usage

|

medical supplies

|

Application

AMEF101-T Medical Sealing Machine(Heat Sealer) is specialized for continuous working on heat sealing for paper-plastic pouches, 3D paper-plastic pouches and paper-paper pouches at site without limitation on pouch width. It also equipped with counting function of high speed, high efficiency, precisive temperature control, easy operation, and stable sealing quality. This upgraded version of conventional heat sealing device meets the requirement of GMP Certificate and related standard both in home and abroad. The main function is to seal the pouches of medical devices prior to sterilization and this machine can meet the requirements of high-temperature steam sterilization, low-temperature ethylene oxide sterilization, hydrogen peroxide plasma sterilization and radiation sterilization.

|

The material available to seal

|

Combined sealable pouches and coiled materials compliance with EN868-5 and YY/T 0698-5;

Paper pouches compliance with EN868-4 and YY/T 0698-4

|

||||||

|

High density polyethylene material(e. g. Tyvek)

|

|||||||

|

Aluminum foil materials.

|

|||||||

|

Unsealed material

|

Polyethylene film

|

||||||

|

Soft pvc firm pvc

|

|||||||

|

Nylon film, polypropylene film.

|

|||||||

Product Features

1. 7” colored LCD capacitive touch screen, Android operating system, functioning in graphical operation interface, in-built clock, auto-counter technology (up to 99999), randomly setup of the operation parameters, automatic storage, voice reading with high-fidelity speaker and wireless Wifi.2. No external computer is required and the in-built LCD touch screen can be used to set up or change the operation parameters with different input methods or scanning gun (as an option); the texts such as the operator, division, description of the medical device can be set up or changed and then they will be printed out.

3. Auto self-diagnosis during working is allowed, which makes the operating pressure and operating speed detected by sealing device. Under test condition, the device allows its parameters displayed on screen, and what’s more, device operating speed, pressure and test time can be printed and saved.

4. The device has Printing parameters data bank, or you can connect in-built wireless LAN with wireless router to record and set up sealing parameters. It allows unlimited storage of sealing and printing information which makes traceability and queries of sealing quality possible.

5. Sealing counter in positive sequence(descending sequence) makes accurate sealing quantity counting possible.

6. Smart computer temperature control design, randomly working temperature between 60℃ and 220℃ set up,temperature control precision ±1%.

7. High speed heating system design: 60 seconds heated from 20℃ to 180℃; 10 seconds needed from 120℃ to 180℃ for common working temperature heating. High efficiency and energy saving allows fast paced working requirement.

8. Auxiliary cooling design: equipped with micro-computer control design to shorten waiting time from high sealing temperature to low sealing temperature. Only 40 seconds needed to descending sealing temperature from 180℃ to 120℃ during normal working which improves working efficiency.

9. Security: the device will stop operating automatically when sealing temperature setting is ±4℃, which ensure the sealing quality and operating security.

10. Sealing speed 10m/min,optical-control technology makes automatic testing for sealing and printing possible.

11. Sealing width 12mm, sealing index standard meets the requirement of “WS310.2—2016”and“YY/T 0698.5-2009”.

12. Margin leaves 0-35mm(adjustable).

Leave Your Message:

Write your message here and send it to us.

-

Amain AMEF120/121 Fully automatic heat sealing ...

-

AMAIN OEM/ODM AMHL11 AC/DC Surgical Headlight w...

-

Automatic High Performance Electronic bag seali...

-

Amain Mobile Wireless Dental Equipment X-ray Ma...

-

Amain Electric Dental Chair For Hospital Dental...

-

AMAIN OEM/ODM AMHL12 Wireless Surgical Headligh...