|

item

|

value

|

|

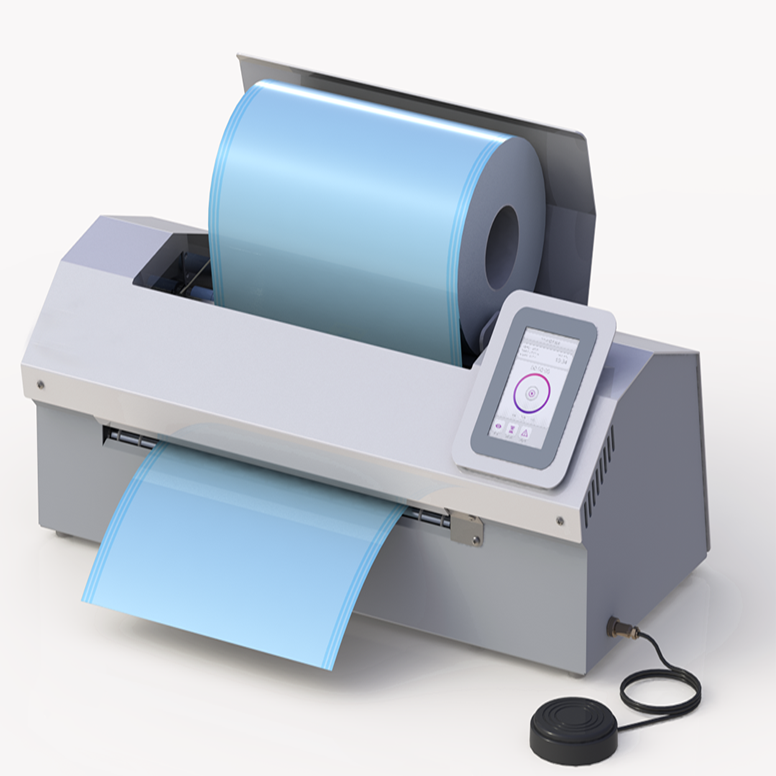

Type

|

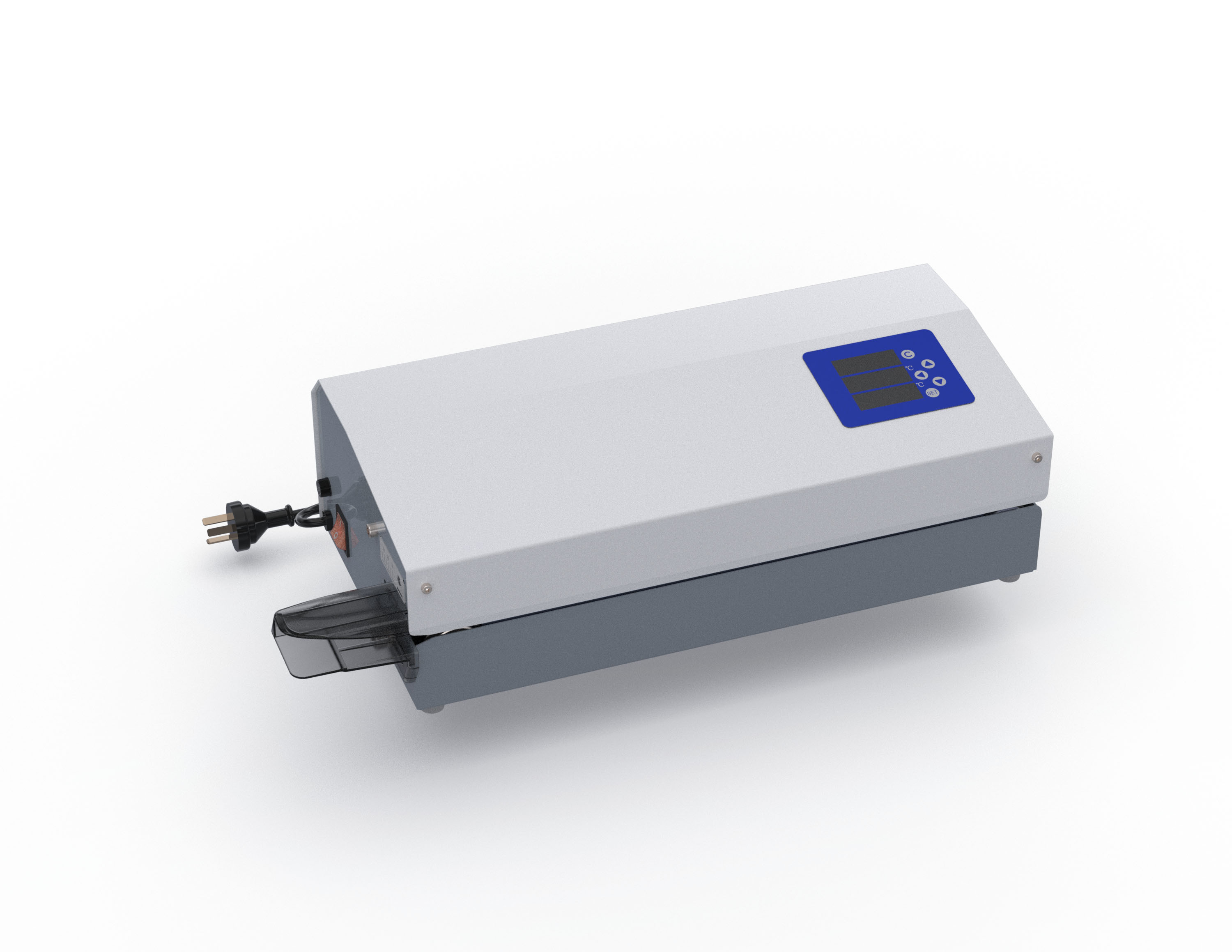

AMEF 058

|

|

Applicable Industries

|

Medical manufacturer, Medical supply factory etc.

|

|

Control system

|

5 ” color LCD capacitive touch screen

|

|

Sealing width

|

10mm

|

|

Cutting width

|

≤400mm (multiple rolls can be cut at the same time)

|

|

Cutting length

|

≥50mm

|

|

Cutting speed

|

2 seconds each time

|

|

Cutting accuracy

|

≤ 1%

|

|

Application

|

Medical

|

|

Automatic Grade

|

automatic

|

|

Driven Type

|

Electric

|

|

AC Power

|

220V±10% 50Hz

|

|

Maximum current

|

3.2 A

|

|

Fuse

|

5A×2

|

|

Working Temperature

|

60~220℃ adjustable

|

|

Temperature error

|

Less than (+1%~-1%)

|

|

Maximum power

|

800w

|

|

Place of Origin

|

China

|

|

Brand Name

|

Amain

|

|

Dimension(L*W*H)

|

666 × 310 × 276 (length × width × height) mm (excluding guide plate)

|

|

Weight

|

33KG

|

|

Warranty

|

1 Year

|

|

Key Selling Points

|

High efficiency

|

|

Marketing Type

|

Hot Product 2020

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

1 Year

|

|

Storage condition

|

Temperature : 0~55℃

Humidity: ≤90%(R.H)

Atmospheric pressure: 50KPa~106KPa

|

|

Working environment:

|

10 ~ 40 ℃

|

|

After-sales Service Provided

|

Online Support

|

|

Function

|

automatic cutting and sealing at the same time

|

|

Keyword

|

medical automatic cutting and sealing machine

|

|

Suitable for

|

cutting and sealing medical supplies before disinfection

|

|

Usage

|

medical supplies

|

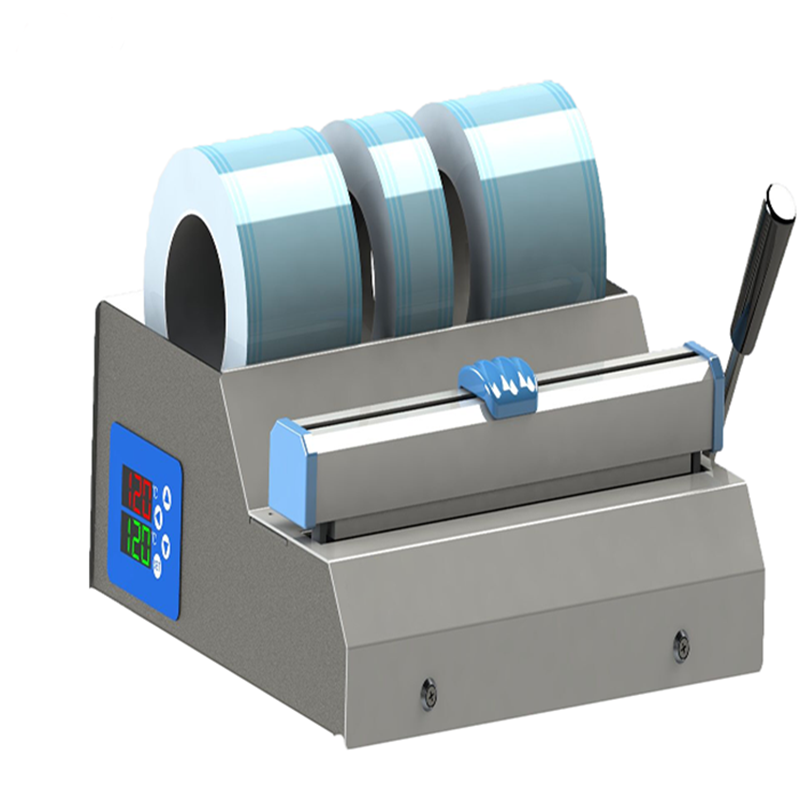

2.If necessary, several rolls of paper-plastic pouches with different widths could be loaded into the machine at the same time to improve its working efficiency by cutting off the edges simultaneously.

|

The material available to seal

|

Combined sealable pouches and coiled materials compliance with EN868-5 and YY/T 0698-5;

Paper pouches compliance with EN868-4 and YY/T 0698-4

|

||||||

|

High density polyethylene material(e. g. Tyvek)

|

|||||||

|

Aluminum foil materials.

|

|||||||

|

Unsealed material

|

Polyethylene film

|

||||||

|

Soft pvc firm pvc

|

|||||||

|

Nylon film, polypropylene film.

|

|||||||

1.5 inch color LCD capacitive touch screen, graphical user interface, built-in clock, and cutting heat sealing the working

parameters has arbitrarily set and automatically store operation information and other functions;

2. With independent roll bag cutting and separate heat sealing function, it can realize multiple uses of one machine and effectively improve work efficiency;

3.With automatic bag cutting and sealing function, you only need to set the required length and quantity of roll bags according to actual needs . After starting the program, the device can complete automatic paper feeding, automatic cutting and automatic heat sealing;

4. May be implemented in a single volume or simultaneously cutting the same size as a multi-volume work, high-precision cutting can be provided according to the implemented volume bag cut precise, time-saving and material saving, reliable deviation is small, the user needs to use large quantities;

5. According to the actual needs, multiple rolls of the same or different width roll bags can be loaded at one time to realize the cutting and sealing of multiple rolls at the same time, thereby improving the working efficiency of the machine;

6. Comes with a count sealing counter, which is convenient for users to accurately count the number of sealing;

7. Computer intelligent temperature control design, the working temperature can be set arbitrarily 60 ~ 220 , the temperature control accuracy is 1%;

8. High-speed heating design: It only takes 60 seconds to rise from 20 to 180 , and it takes only 10 seconds to change the common working temperature from 120 to 180 .

9. Safety: The sealing temperature exceeds the

set temperature range of 4 C, the machine will automatically stop working, effectively ensuring the quality of the sealing and the safe operation of the equipment;

10. Cutting speed of 10 m / min, automatic control of cutting and sealing by light control technology

11. The sealing width is 10 mm, and the sealing index meets the requirements of the standards ” WS310.2 — 2016 ” and “YY / T 0698.5-2009″;

12. Fault automatic alarm indication, which can realize the automatic detection of the working process, and various faults and precautions can be automatically alarmed or prompted;

13. Complete accessories, optional peripheral configurations such as ultra-quiet roller table and multi-function sealing machine workstation produced by our company can improve equipment utilization and facilitate user’s use.